Details according to drawings (machining)

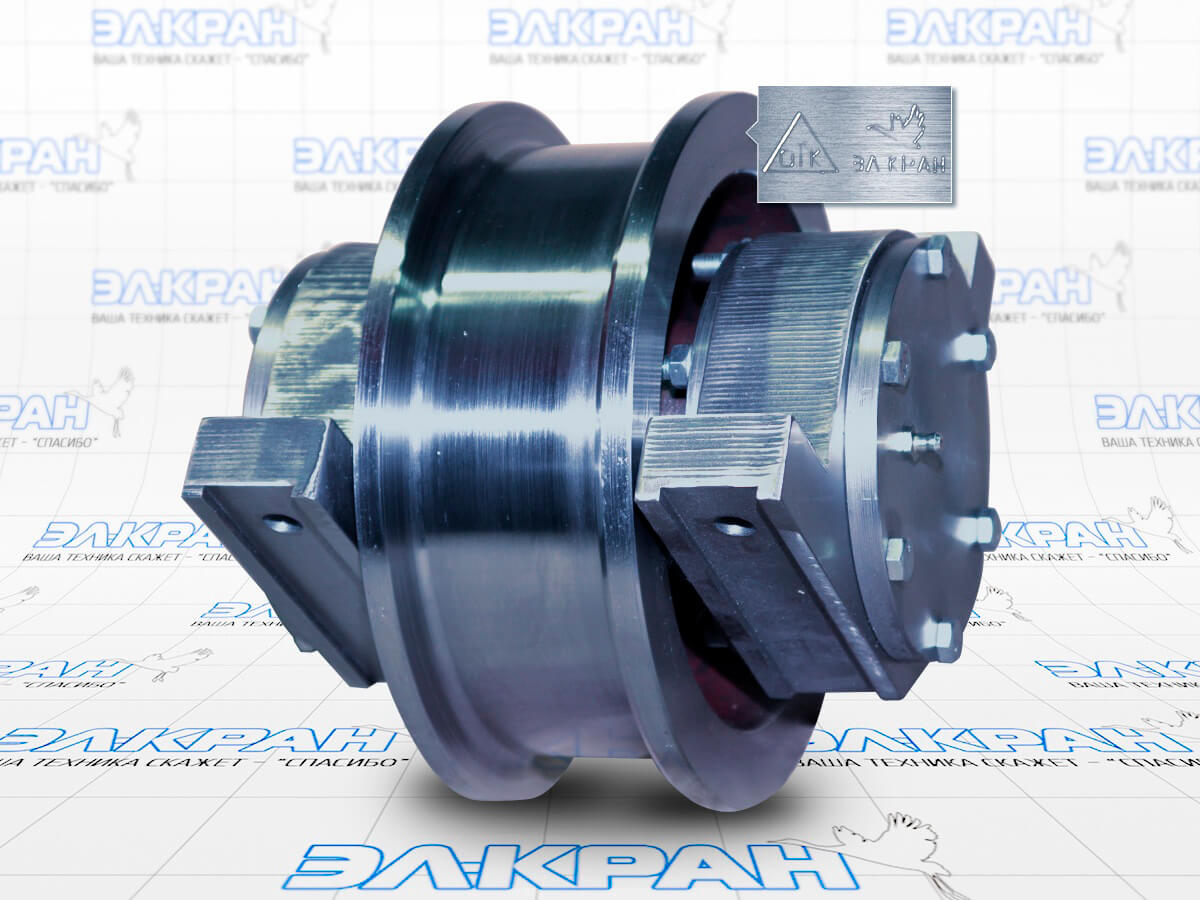

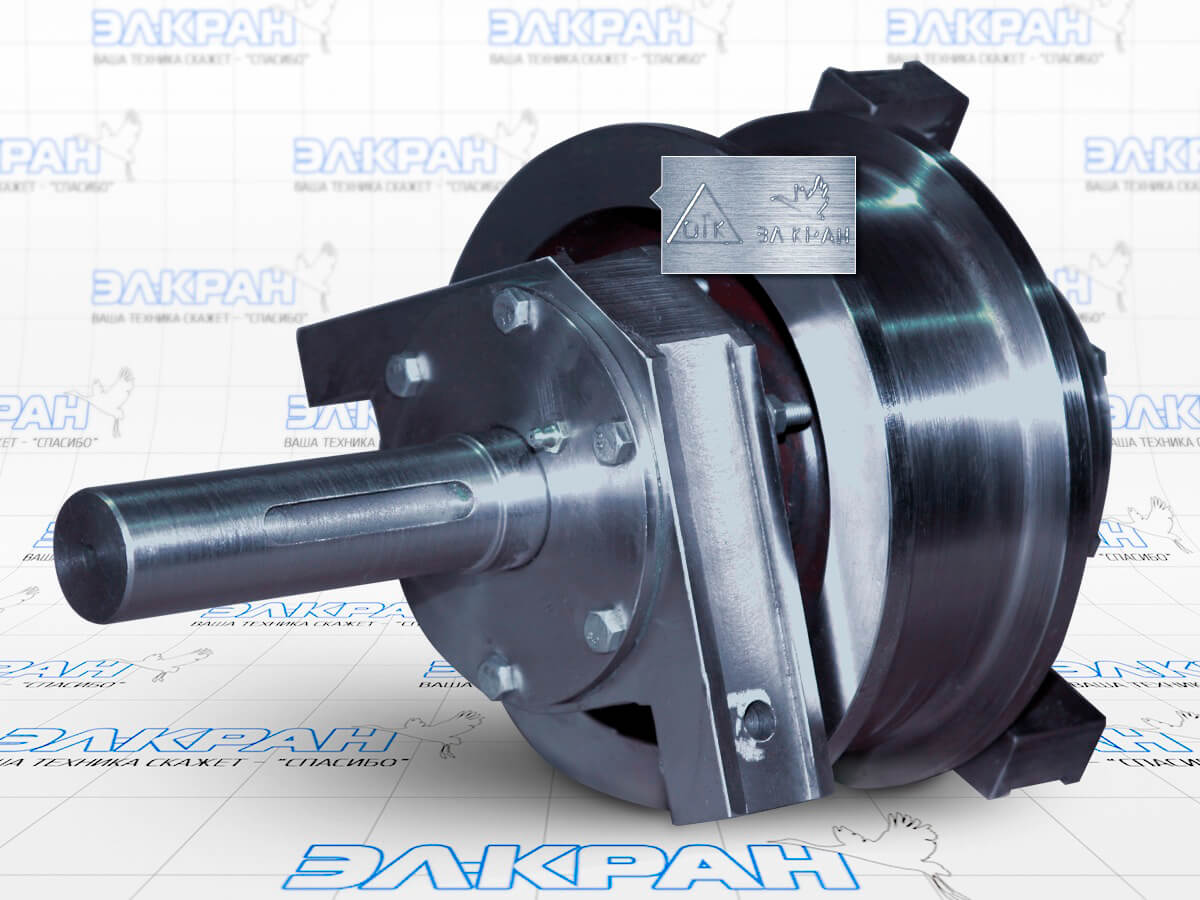

Usually, mechanical processing of metal blanks is required when it’s impossible to select the necessary part among the manufactured ones. Manufacturing parts by customer's design is usually qualified as "Non-standard" orders. The most common methods of manufacturing the blank parts are the manufacturing of shafts by customers design, and restoration of crowns, gears and sprockets. They usually wear the most in the lifting mechanisms and jibs of crane equipment.

- breakage or cracks;

- decsrease of the tooth thickness;

- crushing or chipping of the working surface of the teeth;

- crushing, chipping or shearing of the ends of the teeth;

- complete or partial tooth breakage.

- breakage or cracks;

- damage or absence of centers;

- curvature of the shaft;

- twisting of the shaft;

- damage to keyways, splines and grooves;

- change in shape and damage to the surface of the trunnions.

- decsrease of the tooth thickness;

- crushing or chipping of the working surface of the teeth;

- crushing, chipping or shearing of the ends of the teeth;

- complete or partial tooth breakage;

- cracks in the rim of the wheels or their breakage;

- crack in the hub;

- development of a keyway.

- decsrease of the tooth thickness;

- crushing or chipping of the working surface of the teeth;

- crushing, chipping or shearing of the ends of the teeth;

- complete or partial tooth breakage;

- cracks in the rim of the wheels or their breakage.

Manufacturing of metal products by designs - machining of blanks

Our company has accumulated significant experience, which allows us to manufacture non-standard equipment according to customer designs, as well as to restore the drawings themselves. We are ready to perform work of almost any degree of complexity. Terms depend on the task and spread from 5 to 10 days. The general parameters of the main work on the machining of metal blanks can be seen below.

Table 23. Main parameters of work on mechanical manufacturing of metal workpieces

| NAME | SPECIAL CONDITIONS / RESTRICTIONS |

|---|---|

| Turning work |

|

| Milling |

|

| Grinding |

|

| Drilling |

|

| Gear-cutting and spline-milling work | Maximum module -10 |